VCAS™ White Pozzolans

Recently ASTM recognized ground Glass Pozzolans in a new standard ASTM C 1866. The standard identifies two types of glass. Type GS is soda-lime glass (Vitro ACAS Grades) used to make beverage containers and plate glass windows. Type GE is E Glass (Vitro VCAS Grades) used to make fiberglass reinforcements. Both types glass are very pure and quite reactive at the required particle size of 95% passing 325 mesh (about 4000 Blaine) The major difference between the two types is that type GE effectively mitigates ASR for even the most reactive aggregates like the New Mexico and Spratt aggregates, whereas Type GS, while very pozzolanic, will not mitigate ASR due to a 12% alkali content. Type GS has two subcategories, Plate glass (ACAS Grades) and bottle glass. The ACAS Plate is very white and pure and contains no organic or label remnants. Bottle glass is consumer recycled, tan in color, and must be carefully cleaned to remove organics and label remnants.

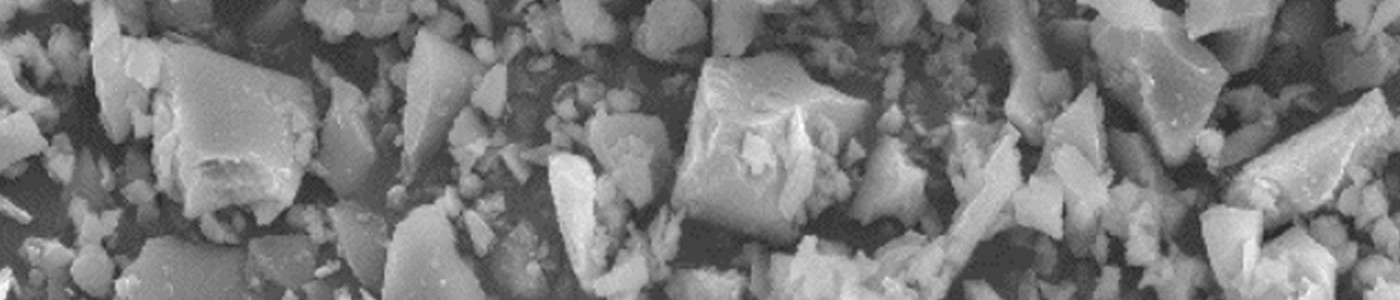

VCAS™ Pozzolans are made from Vitrified Calcium Aluminio-Silicate material having low alkali content, consistent chemistry, uniform color and a wholly amorphous (glassy) state caused by rapid water quenching of the extruded molten material. After primary sizing and drying, the feed stock is finely ground and processed through high efficiency classifiers to produce a fine White powder with quality assured physical properties. The consistent chemical composition and tightly controlled particle size distribution offers excellent repeatability of properties in concrete applications. Currently, the VCAS™ patented technology produces pozzolans in three grades: VCAS™ Ultra 200, VCAS™ 140 and VCAS™ 160.

VCAS 160™ and VCAS™ 140 are commonly used in systems with low w/c ratio and steam cured or warm weather curing conditions where the lower reactivity associated with an 4000 Blaine product is sufficient for the application. VCAS™ 200 has a much finer particle size and has the reactivities normally associated with silica fume and metakaolin with the advantage of being White in color. All VCAS™ grades exhibit approximately 10% lower water demand than silica fume or metakaolin, and can be used at cement replacement levels of up to 40%.

VCAS™ Pozzolans are “green” construction materials made from industrial by-products that help contribute to the sustainability of cement and concrete. VCAS™ Pozzolans use in concrete replaces an equal amount of cement resulting in energy conservation and CO2 emission reductions from cement manufacturing. For every ton of cement manufactured, about 3.5 million BTUs energy are consumed and one ton of carbon dioxide is released.

Vitro Minerals has three types of glass pozzolans; Type GE Glass VCAS Grades, Type GS Plate glass ACAS Grades and HR 50 Fumed Nanosilica Glass, an extremely reactive, very white pozzolan to replace silica fume.

Product Uses

Pozzolan for cement, mortar, concrete, stucco, faux stone and related products.